PHQ (light) model suits to brittle materials of mohs hardness grade 2, including coal, gangue, coke, slag, shale and etc..

PHZ (heavy) model is for different kinds of rocks of mohs hardness grade 5 and below, including limestone, magnetic iron ore, phosphorous ore and etc..

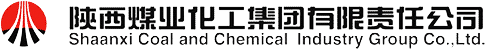

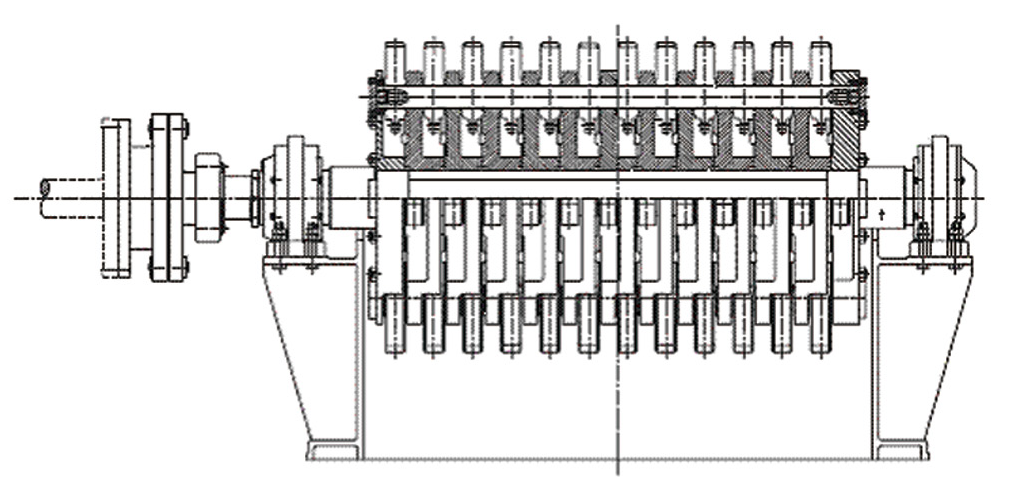

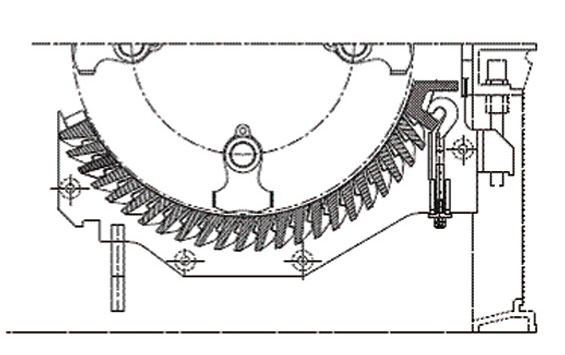

The ring hammer can not only rotate with rotor but also self-rotate around hammer axis pin. After being fed into the crusher, the material are impacted and broken in the cavity by ring hammers rotating at high speed with rotor. With kinetic energy from ring hammer, the broken material are thrown into breaker plates and crushed for the second time while failing on the screen plates. The material are further crushed with shearing, squeezing and grinding by ring hammers and intra-collision, and finally are discharged out of the crusher through screen holes. The unbreakable impurities are pushed into metal collector to be cleaned up by operators. Product size is adjusted by replacing different models of screen plates. The gap between rotor and screen plates can be modified through a regulator mechanism.

|

Model No. |

Output(t/h) |

Feed size(mm) |

Product size(mm) |

Motor power(kw) |

|

PHQ/Z1108 |

200 |

≤250 |

≤25 |

132 |

|

PHQ/Z1111 |

300 |

≤250 |

≤25 |

185 |

|

PHQ/Z1114 |

400 |

≤250 |

≤25 |

250 |

|

PHQ/Z1117 |

500 |

≤250 |

≤25 |

315 |

|

PHQ/Z1218 |

600 |

≤300 |

≤25 |

355 |

|

PHQ/Z1221 |

800 |

≤300 |

≤25 |

450 |

|

PHQ/Z1226 |

1000 |

≤300 |

≤25 |

560 |

|

PHQ/Z1229 |

1200 |

≤300 |

≤25 |

630 |

|

PHQ/Z1825 |

1400 |

≤400 |

≤25 |

710 |

|

PHQ/Z1828 |

1700 |

≤400 |

≤25 |

1100 |

|

PHQ/Z1831 |

2000 |

≤400 |

≤25 |

1200 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube