Mainly used to crush

Coal for circulating fluidized bed boiler

Coking coal for coke even

Coal, coke, limestone, dolomite, lime and etc. for sinter plant

All kinds of low and medium hardness ore, such as iron ore, phosphate rock and etc.

Main features and advantages

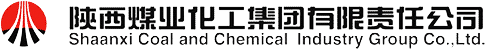

Advanced design and various functions

Higher efficiency and reliable operation

Excellent uniformity of product size and low fine grain ratio

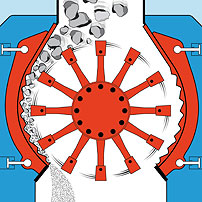

After entering the crushing cavity, the feed material is grasped by the rotating beater heads and then thrown against the grinding face at high speed to be crushed and again rebound to beater heads. The material is gradually crushed in a course of dash and inter-collision repeatedly and discharged out of the end of grinding face.

Product size is determined by rotation speed of the rotor, weight of hammers and gap between the rotor and the grinding wall.

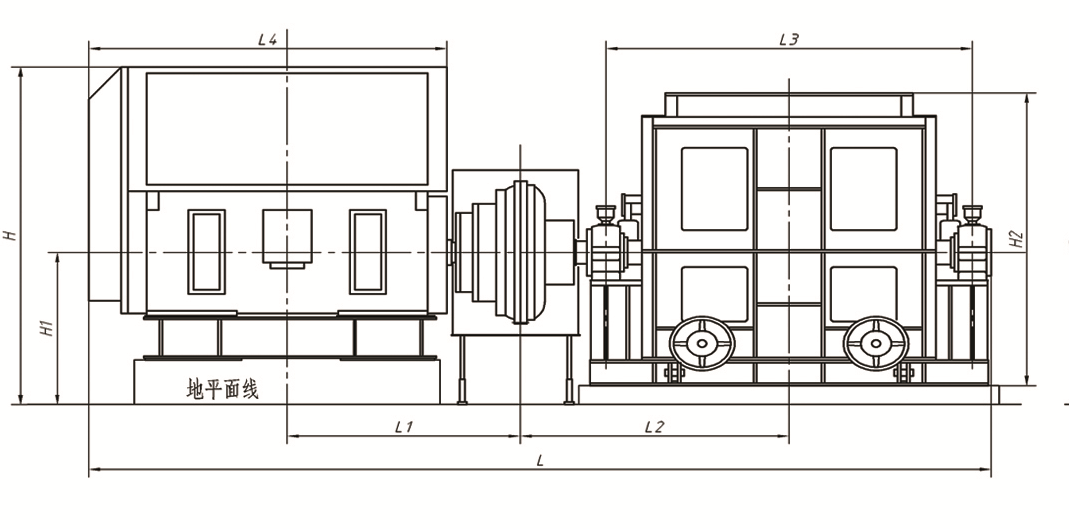

|

Model no. |

Output (t/h) |

Feed size(mm) |

Output size(mm) |

Motor power(kw) |

Rotor diameter(mm) |

Rotor length(mm) |

|

PCFK1006 |

10-15 |

≤50/20 |

≤8/3 |

55 |

1000 |

600 |

|

PCFK1008 |

20-30 |

≤50/20 |

≤8/3 |

75 |

1000 |

800 |

|

PCFK1010 |

30-40 |

≤50/20 |

≤8/3 |

90 |

1000 |

1080 |

|

PCFK1012 |

50-60 |

≤50/20 |

≤8/3 |

132 |

1000 |

1240 |

|

PCFK1210 |

60-70 |

≤70/30 |

≤8/3 |

160 |

1200 |

1080 |

|

PCFK1212 |

80-90 |

≤70/30 |

≤8/3 |

185 |

1200 |

1240 |

|

PCFK1214 |

110-120 |

≤70/30 |

≤8/3 |

250 |

1200 |

1400 |

|

PCFK1414 |

130-150 |

≤70/30 |

≤8/3 |

280 |

1400 |

1400 |

|

PCFK1416 |

160-190 |

≤70/30 |

≤8/3 |

315 |

1400 |

1640 |

|

PCFK1612 |

140-160 |

≤80/30 |

≤8/3 |

355 |

1600 |

1240 |

|

PCFK1616 |

200-220 |

≤80/30 |

≤8/3 |

450 |

1600 |

1640 |

|

PCFK1618 |

250-280 |

≤80/30 |

≤8/3 |

630 |

1600 |

1800 |

|

PCFK1820 |

350-400 |

≤80/30 |

≤8/3 |

710 |

1800 |

2000 |

|

PCFK1825 |

500-550 |

≤80/30 |

≤8/3 |

800 |

1800 |

2500 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube